Ukukhetha umshini ofanele wentambo ye-chenille kuba nomthelela omkhulu ekukhiqizeni nasekuzuzeni inzuzo kwebhizinisi. Imishini eyenzelwe izidingo ezithile ithuthukisa ukusebenza kahle kanye nekhwalithi yomkhiqizo. Isibonelo, imakethe yezintambo, i-fiber, nentambo izokhula isuka ku-$100.55 billion ngo-2024 iye ku-$138.77 billion ngo-2029, okukhombisa ukukhuphuka kwesidingo. Amabhizinisi kufanele ahlole izici ezifana nohlobo lomshini, izindleko, nezici. Ukuhlanganyela nomuntu onokwethenjelwaumkhiqizi wemishini yentambo ye-chenilleiqinisekisa ukufinyelela kubuchwepheshe obusezingeni eliphezulu kanye nokwesekwa kwesikhathi eside.

Okuthathwayo Okubalulekile

- Ukukhetha ilungeloumshini wezintambo ze-chenilleisiza ibhizinisi lakho ukuthi likhule. Bheka izinhlobo zemishini, izintengo, nezici ukuze ukhethe ngokuhlakanipha.

- Cabanga nge-automation kanye nobuchwepheshe lapho uthenga umshini. Imishini ezenzakalelayo isebenza ngokushesha futhi idinga abasebenzi abancane, ilungele izimboni ezinkulu.

- Ukunakekela imishini kubaluleke kakhulu. Hlela ukuhlolwa njalo ukuze ugweme izinkinga futhi ugcine izinga liqinile.

Izinhlobo Zemishini Yentambo Ye-Chenille

Imishini Yezandla

Imishini ye-chenille esetshenziswa ngesandla ilungele ukusebenza kwabancane noma amabhizinisi asanda kuqala. Le mishini idinga ukungenelela komuntu ezinqubweni eziningi, enikeza ukulawula okuphelele ekukhiqizeni. Ayabiza futhi alungele ukukhiqiza amanani alinganiselwe wezintambo. Kodwa-ke, bafuna opharetha abanamakhono ukuze baqinisekise ikhwalithi engaguquki. Amabhizinisi anenani eliphansi lokukhiqiza ngokuvamile akhetha le mishini ngenxa yobulula bayo kanye nokuthengeka kwayo.

Imishini ye-Semi-Automatic

Imishini ye-semi-automatic yenza ibhalansi phakathi kwesistimu yezandla kanye ne-automated ngokugcwele. Benza izinqubo ezithile ngokuzenzakalelayo kuyilapho zisadinga okokufaka komsebenzisi kwabanye. Le nhlanganisela ithuthukisa ukusebenza kahle ngaphandle kokuyekethisa ukulawula. Le mishini iwafanele kahle amabhizinisi aphakathi nendawo ahlose ukukala ukukhiqizwa ngaphandle kokutshalwa kwezimali okubalulekile kwangaphambili. Ukuguquguquka kwazo kuzenza zibe yinketho ethandwayo kumabhizinisi ashintshayo ukusuka kumasistimu okwenziwa ngesandla kuya kumasistimu azenzakalelayo.

Imishini Ezenzakalelayo Ngokugcwele

Imishini yentambo ye-chenille ezenzakalelayo ngokuphelele imelela isiqongo sokusebenza kahle nobuchwepheshe. Le mishini iphatha yonke inqubo yokukhiqiza ngokungenela kwabantu okuncane, iqinisekisa ukuphuma kwesivinini esiphezulu kanye nekhwalithi engaguquki. Zilungele abakhiqizi abakhulu abahlose ukuhlangabezana nezidingo eziphezulu zokukhiqiza. Izici ezithuthukisiwe, ezifana nezilungiselelo ezihlelekayo nokuqapha kwesikhathi sangempela, zenza le mishini ibe yimpahla ebalulekile yamabhizinisi afuna ukuthuthukisa ukusebenza.

Imishini Ekhethekile Yezinhlobo Zezintambo Ezihlukile

Imishini ekhethekile yentambo ye-chenille ibhekelela amabhizinisi akhiqiza izinhlobo ezihlukile noma ezenziwe ngokwezifiso. Le mishini yakhelwe ukuphatha izinto ezithile noma izinqubo, iqinisekisa imiphumela emihle. Ngokwesibonelo, imishini efakwe isibonakhulu esithuthukisiwe ingakala intambo ephindwe kabili ngokunemba. Ukuhlolwa kokugeza okwenziwa ezindwangu ze-e emishinini yokuthengisa, efana ne-EG10014B39GU1 ka-Haier, kukhombisa ukuqina kwazo ngaphansi kwesivinini sokuyaluza esingu-120 rpm. Amabhizinisi angacela idatha enemininingwane ukuze aqhathanise ukukhiqiza nokusebenza, aqinisekise ukufaneleka okulungile kwezidingo zawo.

| Uhlobo Lokuhlola | Incazelo |

|---|---|

| Isibonakhulu se-Optical | Isithombe somucu ophindwe kabili esikalwa ngu-Leica DVM6. |

| Ukugeza Ukuhlolwa | I-E-textile yawashwa emshinini wokuthengisa (EG10014B39GU1, Haier) imizuzu engu-30. |

| Ukuyaluza Isivinini | I-agitator yomshini yayizungeza ku-120 rpm imizuzu eyi-10 phakathi nomjikelezo wokugeza. |

| Ukutholakala Kwedatha | Okutholakele kungasekelwa idatha etholakala kubabhali uma kunesicelo esifanele. |

Imishini ekhethekile inikela ngokunemba okungenakuqhathaniswa nokwenza ngokwezifiso, okuyenza ibaluleke kakhulu ezimakethe ze-niche.

Izici Ezibalulekile Ongazihlola

Isivinini kanye Nempumelelo

Ijubane nokusebenza kahle yizici ezibalulekile lapho kuhlolwa imishini yentambo ye-chenille. Imishini esheshayo yenza amabhizinisi ahlangabezane nezidingo eziphezulu zokukhiqiza kuyilapho egcina ikhwalithi engashintshi. Ukusebenza kahle kuqinisekisa ukumoshwa kwezinsiza okuncane, kunciphisa izindleko zokusebenza. Imishini ezenzakalela ngokugcwele ivamise ukusebenza kahle kule ndawo, njengoba yenza lula izinqubo futhi inciphise isikhathi sokuphumula. Amabhizinisi ahlose ukukala ukukhiqizwa kufanele abeke phambili imishini enamakhono anesivinini esikhulu kanye nokugeleza komsebenzi okulungiselelwe.

Ukuqina kanye Nokwakha Ikhwalithi

Ukuqina kuthinta ngqo impilo yomshini wentambo ye-chenille. Imishini eyakhiwe ngezinto ezisezingeni eliphezulu imelana nokusetshenziswa isikhathi eside futhi inciphisa imvamisa yokulungisa. Ikhwalithi yokwakha eqinile iqinisekisa ukusebenza okungaguquki, ngisho nangaphansi kwezimo ezinzima. Ukutshala imali emishinini ehlala isikhathi eside kunciphisa izindleko zokuyilungisa zesikhathi eside futhi kuthuthukisa ukuthembeka kokusebenza. Abakhiqizi abanedumela eliqinile lekhwalithi, njengabakhiqizi bemishini yezintambo ze-chenille, ngokuvamile bahlinzeka ngemishini ehlangabezana nalezi zindinganiso.

Okuzenzakalelayo Nobuchwepheshe

I-automation kanye nobuchwepheshe obuphambili kushintsha ukukhiqizwa kwentambo. Imishini efakwe izici eziphambili ithuthukisa ukukhiqiza kanye nekhwalithi yomkhiqizo. Izinzuzo ezibalulekile ze-automation zifaka:

- Ukwanda kokukhiqiza: Ukukhiqizwa okuqhubekayo okunesikhathi esincane sokuphumula.

- Ikhwalithi yomkhiqizo ethuthukisiwe: Ukufana kokukhiphayo kunciphisa amaphutha.

- Ukuphepha kwabasebenzi okuthuthukisiwe: Okuzenzakalelayo kuqeda ukuchayeka emisebenzini eyingozi.

- Ukonga izindleko: Ukwehliswa kwezindleko zabasebenzi kanye nokumosha.

- Ukwanda kokusebenza kahle: Izinqubo zokukhiqiza ezilungiselelwe zinciphisa isikhathi sokungenzi lutho.

- Ukuthatha izinqumo okuqhutshwa yidatha: Imishini ikhiqiza idatha yokuthuthukisa inqubo.

- Ukukhiqiza okusimeme: Imikhuba eco-friendly inciphisa ukumoshwa kwezinsiza.

Amabhizinisi kufanele ahlole imishini enezilungiselelo ezihlelekayo, ukuqapha kwesikhathi sangempela, namandla okuhlaziya idatha ukuze ahlale encintisana.

Ukuhambisana Kwezinto ezibonakalayo

Ukuhambisana kwezinto kunquma ukuguquguquka komshini wentambo ye-chenille. Imishini kufanele iphathe izinhlobo ezahlukene zezintambo ngaphandle kokwehliswa kwekhwalithi. Ucwaningo lugqamisa ukubaluleka kokuthuthukisa amapharamitha womshini wezinto ezihlukile. Ngokwesibonelo:

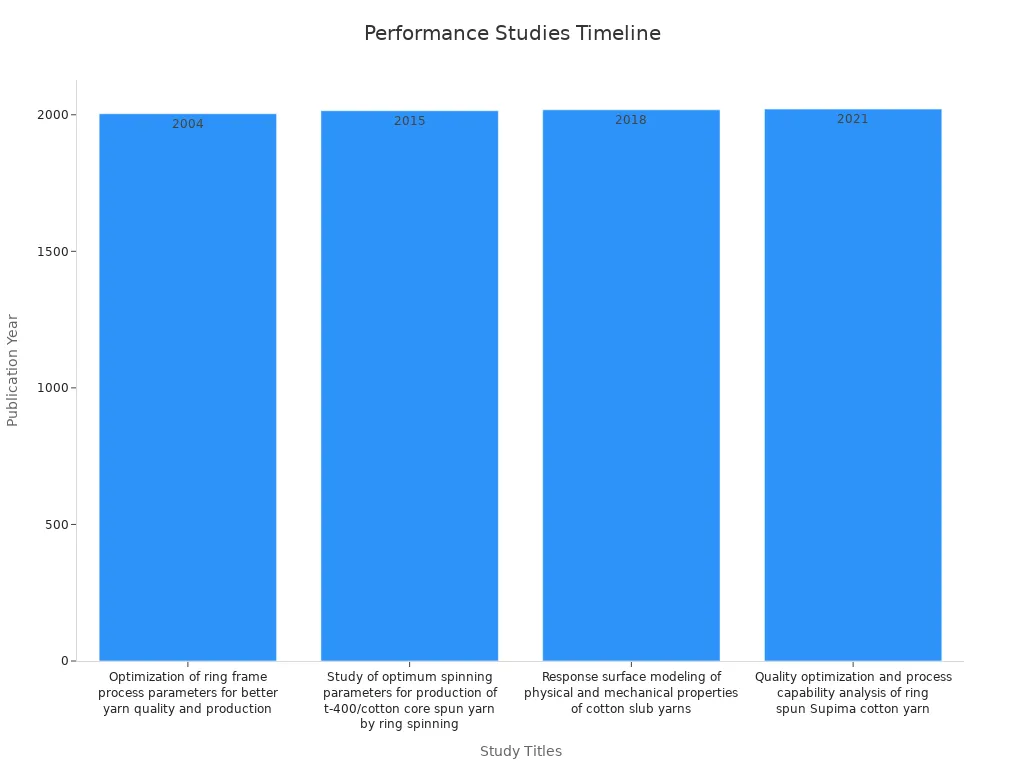

| Isihloko Sokufunda | Ababhali | Ijenali | Unyaka | I-DOI |

|---|---|---|---|---|

| Ukwenziwa ngcono kwekhwalithi nokuhlaziywa kwamandla enqubo yochungechunge lukakotini oluphothelwe indandatho ye-Supima | NT Akankwasa, J. Wang, Y. Zhang | De Gruyter | 2021 | 10.1515/mt-2021-0027 |

| Ucwaningo lwamapharamitha wokuphotha angcono kakhulu wokukhiqizwa kwe-t-400/ukotini oyinhloko ophotha intambo ngokuphotha indandatho | NT Akankwasa, J. Wang, Y. Zhang | Ijenali yeThe Textile Institute | 2015 | 10.1080/00405000.2015.1045254 |

| Imodeli yendawo yokusabela yezakhiwo ezingokoqobo nezomshini zezintambo ze-slub zikakotini | MB Qadir, ZA Malik, U. Ali, A. Shahzad, T. Hussain, A. Abbas, M. Asad, Z. Khaliq | I-Autex Research Journal | 2018 | 10.1515/aut-2017-0025 |

| Ukuthuthukiswa kwamapharamitha wenqubo yohlaka lwendandatho ukuze uthole ikhwalithi engcono yentambo nokukhiqizwa | S. Ishtiaque, R. Rengasamy, A. Ghosh | I-Indian Journal of Fiber and Textile Research | 2004 | N/A |

Ukukhetha imishini ehambisana nezinto ezihlukahlukene kuqinisekisa ukuguquguquka nokuvumelana nezimo ekukhiqizeni.

Idizayini Elungele Umsebenzisi

Imiklamo esebenziseka kalula yenza kube lula ukusebenza nokugcinwa komshini. Izici ezifana nezindawo zokusebenzelana ezinembile, izilawuli ze-ergonomic, nokufinyelela okulula ezingxenyeni kuthuthukisa ukusebenziseka. Imishini enemiklamo eqondile inciphisa isikhathi sokuqeqeshwa komsebenzisi futhi ithuthukise ukukhiqiza. Amabhizinisi kufanele abeke phambili imishini elinganisa ukusebenza okuthuthukile nokusebenziseka kalula, iqinisekise ukuhlanganiswa okungenamthungo ekugelezeni komsebenzi okukhona.

Ukuqondanisa Amakhono Omshini Nezidingo Zebhizinisi

Ukuhlolwa Kwevolumu Yokukhiqiza

Ukuqonda izidingo zevolumu yokukhiqiza kubalulekile lapho ukhetha aumshini wezintambo ze-chenille. Amabhizinisi kufanele ahlole umkhiqizo wawo wamanje futhi abikezele isidingo sesikhathi esizayo ukuze anqume umthamo womshini. Imishini eklanyelwe ukukhiqizwa kwevolumu ephezulu, njengamamodeli azenzakalelayo ngokuphelele, ahlinzekela abakhiqizi abanomsebenzi omkhulu. Ngokuphambene, imishini yezandla noma e-semi-automatic ifanela amabhizinisi anezidingo zokukhiqiza ezimaphakathi noma ze-niche.

Ukuhlolwa kwevolumu yokukhiqiza kubandakanya nokuhlaziya ukuguquguquka kwezinkathi ezithile zonyaka kanye nezitayela zemakethe. Isibonelo, amabhizinisi akhiqiza intambo ye-chenille yezingubo zasebusika angase abe nesidingo esiphezulu phakathi nezinyanga ezibandayo. Imishini enezilungiselelo ezilungisekayo ivumela abakhiqizi ukuthi bakhulise ukukhiqiza ngendlela efanele ngesikhathi sesidingo esikhulu. Ngokuqondanisa umthamo womshini nezinjongo zokukhiqiza, amabhizinisi angagwema ukusetshenziswa kancane noma ukulayishwa ngokweqile, aqinisekise ukusebenza kahle.

Ukufanisa Izici Nezinjongo Zebhizinisi

Ukukhetha umshini oqondana nezinjongo ezithile zebhizinisi kudinga ukuqonda okucacile kwezinto ezibalulekile zokusebenza. Isibonelo, amabhizinisi agxile ekuzinzeni angase abeke kuqala imishini enezici ezonga amandla. Abakhiqizi abahlose ukunemba ekwakhiweni kwentambo yangokwezifiso bayahlomula emishinini ekhethekile ehlonyiswe ngobuchwepheshe obuphambili.

Ubunjiniyela besici budlala indima ebalulekile kule nqubo. Imishini enezilungiselelo ezihlelekayo nokuqapha kwesikhathi sangempela ithuthukisa ukunemba kokusebenza, iqondaniswe nezidingo zokukhiqiza. Amabhizinisi angasebenzisa lezi zici ukuze alungiselele ukugeleza komsebenzi, anciphise ukumosha, futhi athuthukise ikhwalithi yomkhiqizo. Umkhiqizi wemishini yentambo ye-chenille ethembekile uvame ukuhlinzeka ngemishini eklanyelwe izidingo zebhizinisi ezahlukahlukene, eqinisekisa ukuhlanganiswa okungenamthungo ekusebenzeni okukhona.

Ukucatshangelwa Kwendawo Nengqalasizinda

Indawo ebonakalayo nengqalasizinda etholakala esikhungweni ithonya kakhulu ukukhethwa komshini. Imishini emikhulu idinga indawo eyanele yokufaka nokusebenza, okuyenza ifaneleke amabhizinisi anezindawo ezinkulu zokukhiqiza. Imishini emincane, ngakolunye uhlangothi, ibhekelela amabhizinisi anendawo elinganiselwe, enikeza ukukhiqizwa okuphumelelayo ngaphandle kokubeka engcupheni ikhwalithi.

Ukuhambisana nengqalasizinda kubalulekile ngokufanayo. Imishini kufanele ihambisane namazinga kagesi esikhungo, umoya omncane kanye nezokuphepha. Isibonelo, imishini ezenzakalelayo ngokugcwele ngokuvamile idinga okokufaka kwamandla aphezulu kanye nezinhlelo zokupholisa ezithuthukisiwe. Amabhizinisi kufanele ahlole amakhono awo engqalasizinda ngaphambi kokutshala imali emshinini ukugwema ukuphazamiseka kokusebenza. Ukuhlela kahle kuqinisekisa ukufakwa okushelelayo nokusebenza kwesikhathi eside.

I-Scalability Yokukhula

Ukuqina kuyisici esibalulekile kumabhizinisi ahlose ukukhulisa imisebenzi yawo. Imishini enemiklamo ye-modular nezici ezingathuthukiswa isekela ukukhula ngokuzivumelanisa nezimfuneko ezikhulayo zokukhiqiza. Isibonelo, imishini ye-semi-automatic ingathuthukiswa ibe amasistimu azenzakalelayo ngokuphelele, okuvumela amabhizinisi ukuthi akhule kahle.

Ukutshala imali emishinini eyokwehla kuqinisekisa inzuzo yesikhathi eside nokuvumelana nezimo. Amabhizinisi angaphendula izinguquko zemakethe kanye nezidingo zamakhasimende ngaphandle kokutshalwa kabusha okubalulekile. Umkhiqizi wemishini yentambo ye-chenille ehlinzeka ngezixazululo ezingaka ihlinzeka amabhizinisi ngamathuluzi okufinyelela ukukhula okusimeme. Ngokubeka phambili ukwehla, abakhiqizi bangakwazi ukufakazela ukusebenza kwabo esikhathini esizayo futhi balondoloze umkhawulo wokuncintisana.

Imininingwane Yezindleko Nesabelomali

Ukutshalwa Kwezimali Okuphambili

Izindleko zokuqala ze-aumshini wezintambo ze-chenilleimele ingxenye ebalulekile ye-investimenti iyonke. Amabhizinisi kufanele ahlole isabelomali sawo kanye nezidingo zokukhiqiza ukuze anqume umshini ofaneleka kakhulu. Imishini ezenzakalelayo ngokugcwele ivamise ukudinga ukutshalwa kwezimali okuphezulu kwangaphambili ngenxa yezici zayo ezithuthukile nobuchwepheshe. Kodwa-ke, imishini yezandla kanye ne-semi-automatic inikeza izinketho ezithengekayo kumabhizinisi anemali elinganiselwe.

Ithiphu: Cabanga ngezinzuzo zesikhathi eside zokutshala imali emishinini yekhwalithi ephezulu. Imishini ehlala isikhathi eside inciphisa izindleko zokulungisa futhi iqinisekisa ukusebenza okungaguquki ngokuhamba kwesikhathi.

Izindleko Zokulungisa Zesikhathi Eside

Izindleko zokunakekela zidlala indima ebalulekile ezindlekweni eziphelele zobunikazi. Imishini enekhwalithi eqinile yokwakha kanye nezingxenye ezithembekile ngokuvamile idinga ukulungiswa kancane. Amabhizinisi kufanele futhi acabangele ukutholakala nezindleko zezingxenye ezisele. Ukubambisana nabakhiqizi abahlinzeka ngokusekela okuphelele kokulungisa kunganciphisa isikhathi sokuphumula futhi kunwebe ubude bempilo yomshini.

Uhlelo lokulungisa olusebenzayo luqinisekisa ukusebenza kahle futhi luvimbela izindleko ezingalindelekile. Ukuseviswa njalo kanye nokushintshwa ngesikhathi kwezingxenye ezigugile kunomthelela ekusebenzeni kahle.

Ukuhlaziywa kwe-ROI

Ukuhlaziywa kwe-Return on investment (ROI) kusiza amabhizinisi ahlole ukusebenza kwezimali kokuthenga kwawo. Imishini enesivinini esikhulu futhi ephumelelayo ivame ukuletha i-ROI esheshayo ngokwandisa umthamo wokukhiqiza nokunciphisa izindleko zabasebenzi. Amabhizinisi kufanele abale isikhathi sokubuyisela ngokuqhathanisa izindleko zomshini nokukhula kwemali engenayo okulindelekile.

Imishini enezinto ezizenzakalelayo ezithuthukisiwe nezici ezonga amandla ngokuvamile ihlinzeka nge-ROI ephezulu, okuyenza ibe ukukhetha okuhlakaniphile kwenzuzo yesikhathi eside.

Izinketho Zokuthola Imali Nokuqashisa

Izinketho zezimali nezokuqashisa zinikeza ukuguquguquka kwebhizinisi elinezingqinamba zesabelomali. Abakhiqizi abaningi banikeza izinhlelo zesitolimende noma izivumelwano zokuqashisa, ezivumela amabhizinisi ukuthi athole imishini ethuthukisiwe ngaphandle kwenkokhelo enkulu yangaphambili. Ukuqashisa futhi kwenza amabhizinisi athuthukele kumamodeli amasha njengoba ubuchwepheshe buthuthuka.

Qaphela: Hlaziya imigomo nemibandela yezivumelwano zezimali ngokucophelela. Izinkontileka ezisobala ziqinisekisa ukuthi amabhizinisi agwema izimali ezifihliwe futhi agcine uzinzo lwezezimali.

Ukunakekela kanye Nokwesekwa Komkhiqizi

Ukubaluleka Okuvamile Kwesondlo

Ukugcinwa okuvamile kuqinisekisa ukuphila isikhathi eside nokusebenza kahle kwemishini ye-chenille yarn. Ukunikeza isevisi okuhleliwe kunciphisa ukuphuka okungalindelekile, kunciphisa isikhathi sokuphumula nokugcina ukukhiqizwa okungaguquki. Ukunakekela okuvimbelayo kusiza futhi ukuhlonza izinkinga ezingase zibe khona kusenesikhathi, kuvimbele ukulungiswa okumba eqolo. Amabhizinisi abeka phambili ukunakekelwa okujwayelekile ahlangabezana neziphazamiso ezimbalwa futhi agcine ukwethembeka okuphezulu kokusebenza. Umshini onakekelwa kahle awugcini nje ngokuthuthukisa ukukhiqiza kodwa futhi uqinisekisa ikhwalithi yomkhiqizo, okubalulekile ekwanelisekeni kwamakhasimende.

Ukutholakala Kwezingxenye Ezisele

Ukutholakala kwezingxenye eziyisipele kudlala indima ebalulekile ekugcineni isikhathi sokusebenza komshini. Amabhizinisi angenakho ukufinyelela ezingxenyeni ezibalulekile abhekana nezinselele ezimbalwa:

- Isikhathi Sokuphumula Esikhulisiwe:Ukumiswa kokukhiqiza ngenxa yezingxenye ezingatholakali kuholela ekulahlekeni kwezimali.

- Izindleko Zokulungisa Eziphakeme:Ukuthengwa kwezingxenye eziphuthumayo kuphakamisa izindleko zokulungisa.

- Ukwethenjwa Kwezisetshenziswa Ezincishisiwe:Ukubambezeleka ekutholeni izingxenye kubangela ukwehlukana okungahleliwe, okuthinta ukwethenjwa kwamakhasimende.

Ucwaningo oluyisibonelo oluvela ku-SAIC GM lugqamisa ukuthi ukutholakala kwezingxenye eziyisipele okuthuthukisiwe kubuqinise kanjani ubudlelwano bomthengisi kanye nenzuzo. Izinkampani kufanele zibambisane nabakhiqizi abahlinzeka ngosekelo olubanzi lwezingxenye eziyisipele ukugwema lezi zingibe. Amathuluzi athuthukile afana ne-CMMS (Izinhlelo Zokuphatha Ukugcinwa Kwekhompyutha) athuthukisa futhi ukuhlelwa kokugcinwa kokuvikela, ukunciphisa isikhathi sokuphumula esingahlelelwe.

Ukusekela Umkhiqizi kanye Newaranti

Ukwesekwa komkhiqizi kuqinisekisa ukuthi amabhizinisi athola usizo olufika ngesikhathi ngezinkinga zobuchwepheshe. Inqubomgomo yewaranti eqinile inikeza ukuthula kwengqondo okwengeziwe. Isibonelo, ukuphotha kwentambo ye-chenille nokwenza imishini ngokuvamile iza newaranti yonyaka owodwa:

| Uhlobo Lomshini | Iwaranti |

|---|---|

| Umshini Wokuphotha Intambo Ye-Chenille | 1 Unyaka |

| Umshini Wokwenza Intambo Ye-Chenille | 1 Unyaka |

Abakhiqizi abathembekile banikeza ukwesekwa okusheshayo, okuqinisekisa ukuphazamiseka okuncane. Amabhizinisi kufanele ahlole ukubuyekezwa kanye nobufakazi ukuze ahlole ikhwalithi yesevisi yangemva kokuthengisa ehlinzekwa ngumkhiqizi wemishini yentambo ye-chenille ekhethiwe.

Ukuqeqeshwa Nosizo Lobuchwepheshe

Ukuqeqeshwa okuphelele nosizo lobuchwepheshe kunika amandla opharetha ukuthi bakhulise ukusebenza komshini. Abakhiqizi abanikeza ukuqeqeshwa okusebenzayo baqinisekisa ukuthi opharetha bayakuqonda ukusebenza komshini kanye nezinqubo zokunakekela. Usekelo lobuchwepheshe, olutholakala ngezingcingo zocingo noma ngokuvakasha kusayithi, luxazulula izinkinga ngokushesha. Lokhu kuhlanganiswa kokuqeqeshwa nosizo kuthuthukisa ukusebenza kahle futhi kunciphisa isikhathi sokuphumula. Amabhizinisi kufanele abeke phambili abakhiqizi abatshala imali ekufundiseni amakhasimende nokwesekwa.

Amathiphu Wokukhetha Umkhiqizi Wemishini Yezintambo Ye-Chenille Ofanele

Imishini Yokuhlola Ngaphambi Kokuthenga

Imishini yokuhlola ngaphambi kokuthenga iqinisekisa ukuthi ihlangabezana nezidingo zokukhiqiza futhi isebenza njengoba kulindelekile. Amabhizinisi kufanele acele imibukiso ebukhoma noma ama-trial run ukuze ahlole amakhono emishini. Ukubuka umshini usebenza kunikeza imininingwane ngesivinini sawo, ukusebenza kahle kwawo, kanye nokusebenza kalula. Isibonelo, ukuhlola kuvumela abakhiqizi ukuthi bahlole ukuthi umshini uyakwazi ukuphatha izinhlobo ezithile zezintambo noma amavolumu okukhiqiza. Le ndlela yokusebenzisana inciphisa ubungozi bokutshala imali kumishini ehlulekayo ukuhambisana nezidingo zebhizinisi.

Ukufunda Ukubuyekezwa kanye Nobufakazi

Ukubuyekeza nobufakazi kunikeza imibono ebalulekile ngokwethembeka komkhiqizi kanye nekhwalithi yomkhiqizo. Amabhizinisi kufanele ahlole impendulo evela kwabanye abasebenzisi ukuze abone amandla afanayo nezinto ezikhathazayo ezingaba khona. Izibuyekezo ezinhle zivame ukugqamisa ukusebenza okungaguquki, ikhwalithi yokwakha eqinile, nokusekelwa kwamakhasimende okuhle kakhulu. Ubufakazi obuvela kontanga bemboni futhi bungaqinisekisa isithunzi somkhiqizi. Ngokuhlaziya le mininingwane, amabhizinisi angenza izinqumo ezinolwazi futhi akhethe uzakwethu othembekile ngemisebenzi yawo.

Consulting Imboni Ochwepheshe

Ochwepheshe bemboni banikeza isiqondiso esibalulekile lapho ukhetha umshini wezintambo ze-chenille. Umuzwa wabo usiza amabhizinisi ukuthi asebenzise imininingwane yobuchwepheshe futhi akhombe imishini efanele izinhlelo zokusebenza ezithile. Ochwepheshe bavame ukuthembela kumasu okuqinisekisa ukuze bahlole ukusebenza komshini. Ngokwesibonelo:

- I-Train-Test Split: Ukwehlukanisa amasethi edatha abe amasethi okuqeqesha nokuhlola kuqinisekisa ukuhlolwa kokusebenza okunembile.

- Ukuqinisekiswa Kwesiphambano se-K-Fold: Ukuhlukanisa idatha ezingxenyeni eziningi kuthuthukisa ukwethembeka, ikakhulukazi kumadathasethi amancane.

Lezi zindlela, zihlangene nezeluleko zochwepheshe, zivumela amabhizinisi ukuthi akhethe imishini eletha imiphumela emihle.

Ukuqhathanisa Izinketho Zomkhiqizi

Ukuqhathanisa abakhiqizi abaningi kuqinisekisa ukuthi amabhizinisi athola okufanelekela izidingo zawo. Izici ezibalulekile okufanele zihlolwe zifaka phakathi ububanzi bomkhiqizo, ukusekela ngemva kokuthengisa, nezinqubomgomo zewaranti. Ithebula lokuqhathanisa lingenza le nqubo ibe lula:

| Umkhiqizi | Ibanga Lomkhiqizo | Iwaranti | Izinsizakalo Zokusekela |

|---|---|---|---|

| Umkhiqizi u-A | Okubanzi | iminyaka engu-2 | 24/7 Ukusekelwa Kwezobuchwepheshe |

| Umkhiqizi B | Kuphakathi | 1 Unyaka | Usizo Olulinganiselwe |

| Umkhiqizi u-C | Okukhethekile | 3 Iminyaka | Ukuqeqeshwa Okuphelele |

Amabhizinisi kufanele abeke phambili abakhiqizi abanikeza amawaranti aqinile nokusekelwa okubanzi. Umkhiqizi wemishini yezintambo ze-chenille onokwethenjelwa akanikezi nje kuphela okokusebenza kwekhwalithi ephezulu kodwa futhi nenani lesikhathi eside ngesevisi eyingqayizivele.

Ukukhetha okulungileumshini wezintambo ze-chenilleibalulekile empumelelweni yebhizinisi. Iqinisekisa ukusebenza kahle, ihambisana nemigomo yokukhiqiza, futhi isekela ukukhula. Okucatshangelwayo okubalulekile kuhlanganisa:

- Izinhlobo zomshini nezici.

- Izindleko nokugcinwa.

- Scalability nengqalasizinda.

- Ukutshalwa kwezimali kwemishini yamasu kukhulisa ukukhiqiza, kulungiselela ukukhula, futhi kuthuthukisa ukuncintisana kwemakethe. Amabhizinisi kufanele abeke phambili izinqumo ezinolwazi ukuze aphumelele esimeme.

FAQ

Ingakanani impilo yomshini wentambo ye-chenille?

Ubude bempilo buncike ekunakekeleni nasekusetshenzisweni. Ngokunakekelwa okufanele, imishini yekhwalithi ephezulu ingahlala iminyaka eyi-10-15 noma ngaphezulu.

Ingabe imishini ye-chenille ingakwazi ukuphatha izinhlobo eziningi zezintambo?

Yebo, imishini eminingi isekela izinhlobo ezihlukahlukene zezintambo. Amabhizinisi kufanele aqinisekise ukuhambisana kwezinto nomkhiqizi ngaphambi kokuthenga.

Umshini we-chenille kufanele ulungiswe kangaki?

Ukunakekelwa okujwayelekile kufanele kwenzeke njalo ezinyangeni ezi-3-6. Ukusevisa okuvamile kuqinisekisa ukusebenza kahle futhi kuvimbela ukuwohloka okungalindelekile.

Isikhathi sokuthumela: Apr-24-2025